| Author |

Message |

|

Markus Fischer

|

Posted: Sat 25 Jul, 2020 4:17 am Post subject: Skills of medival European swordsmiths Posted: Sat 25 Jul, 2020 4:17 am Post subject: Skills of medival European swordsmiths |

|

|

A while ago a fellow hema practitioner said that only 3% of the medival swordsmiths had the knowledge and skill (perhaps also no tools) to harden and temper a swordblade.

That would mean that almost all historical European swords were unhardened steel (maybe the edge was slightly hardened because the smith might have cold-hammered it).

When I heard that I was very sceptical, because this just very unlikely and not logical at all as the swords would instantly bent in combat.

But there is no better way to clarify this than to ask some other sword-nerds, right

|

|

|

|

|

Matthew Amt

|

Posted: Sat 25 Jul, 2020 5:49 am Post subject: Posted: Sat 25 Jul, 2020 5:49 am Post subject: |

|

|

My gut reaction is "hogwash". It's like saying most peasants didn't know how to grow crops or raise chickens, or didn't have the tools to run a farm. You don't GET to be a swordsmith unless you know how to MAKE SWORDS. Period. If you show such little promise as an apprentice, you'll be working the bellows until you die of old age. If you have not tools, you can't set up shop and make swords.

Now, were the techniques for making and hardening steel closely guarded secrets? Sure! Secrets passed from one master to his students, so they could be masters in their turn. Obviously without the microscopic knowledge we have today, it was more of an art than a science, and it seems pretty clear that some swords were better than others. But 3%? I seriously doubt it. Unless someone can show that 97% of surviving swords had no steel.

Swords in ancient Greek and Roman times were frequently iron, and they worked fine. And I *have* heard that there were still plenty of iron swords well into the middle ages. Though one caveat I would add is that it was apparently common for archeologists in the 19th and early 20th centuries to use *annealing* as a method for conserving and stabilizing excavated iron objects, including swords, which of course destroys all trace of how the sword may have been heat-treated originally. Not to mention weapons that may have been on funeral pyres or in burned buildings.

Final note, iron is not lead. It won't just fold up under a normal battlefield blow. If you try to cut down a tree with it, yes, that will be bad, but even good swords are not meant for cutting wood. You *can* make reasonable weapons and armor from plain iron, and it was done quite often in ancient and medieval times.

Matthew

|

|

|

|

|

Markus Fischer

|

Posted: Sat 25 Jul, 2020 10:07 am Post subject: Posted: Sat 25 Jul, 2020 10:07 am Post subject: |

|

|

Yes. That is mostly what I think too. One thing I have to say though: Its a huge differens whether you have an iron Gladius or an iron longsword. The longsword will bent significantly easier, because the blade is longer and (near the tip) narrower in thickness and profile. The length is the most important factor as the leverage is much higher, and also it has a higher tipspeed when you swing it ( the longer blade produces a bigger radius), which makes a lot more force act on the blade.

Furthermore a good sword should be able to chop down a small tree (about 3" diameter)without failing, because in a battle it would slash against helmets, plate armour, other swords and also cut through bone.

Due to all these reasons a iron longsword would be unusable on the medival battlefield.

Therefore I also think, that 3% is very unrealistic.

Maybe I understood my Mate wrongly, and he was refering to the amount of swordsmiths compared to the number of standard blacksmiths.

|

|

|

|

|

Sean Manning

|

Posted: Sat 25 Jul, 2020 11:36 am Post subject: Posted: Sat 25 Jul, 2020 11:36 am Post subject: |

|

|

If you're interested in the metallurgy of western European swords in the 14th / 15th / 16th century, the people to read are Dr. Alan Williams and Prof-Em. Dr. Helmut Föll

If you tried to chop down a tree with most of the swords that have ever been used in battle, I don't think you would like the result. That is just not something that most swords are built to do!

weekly writing ~ material culture

|

|

|

|

|

Peter Lyon

Industry Professional

|

Posted: Sat 25 Jul, 2020 12:13 pm Post subject: Posted: Sat 25 Jul, 2020 12:13 pm Post subject: |

|

|

I would like to know what sources your hema friend based that position on, because as far as I am concerned it is utter rubbish.

Swordsmiths were a specialised group within a specialised field (blacksmithing). Anyone can make a sword, but if you want a good sword that you can your life to, you would go to a swordsmith - or more particularly a bladesmith, as the hilting was often a separate speciality. It was, quite literally, their profession to make good blades.

That said, there are limits imposed by materials and techniques on how good the blade would end up - you cannot grab any old piece of iron and expect it to make a good blade. It would ideally have 0.6-1.4% carbon, and if you are lucky the alloying elements in the parent ore make for an even better steel - this is why places like Solingen became famous for the quality of the blades made there, and why so many swords such as claymores were hilted on to German blades. Bladesmiths served apprenticeships to learn their skills, which often relied on how much your teacher knew and whether their special knowledge was good, but all the basic skills were well known. One of those basic skills was assessing the steel you had for its suitability for blade making. There were limits with the heat treats, but you should get a tough, flexible, blade that will take a good edge and rebound from most abuse. It wasn't magic, it was applied good techniques, just without our modern understandings of the internal workings of steels.

So, anyone can make a crappy sword, and if just anyone did so the sword would be crappy, and liable to get you killed. Buy from a trained bladesmith, and you would get the best blade possible with the materials and techniques available at that moment. The best European blades could be just as good as the work in blades from any other part of the world.

Still hammering away

|

|

|

|

|

Matthew Amt

|

Posted: Sat 25 Jul, 2020 12:47 pm Post subject: Posted: Sat 25 Jul, 2020 12:47 pm Post subject: |

|

|

| Markus Fischer wrote: | | Yes. That is mostly what I think too. |

Good!

| Quote: | | One thing I have to say though: Its a huge differens whether you have an iron Gladius or an iron longsword. The longsword will bent significantly easier, because the blade is longer and (near the tip) narrower in thickness and profile. The length is the most important factor as the leverage is much higher, and also it has a higher tipspeed when you swing it ( the longer blade produces a bigger radius), which makes a lot more force act on the blade. |

I tend to agree, BUT if iron long swords have been found, then the only conclusion we can make is that they did *not* just bend in combat, or otherwise fail in normal use, because anyone making such swords would not be in business very long.

| Quote: | | Furthermore a good sword should be able to chop down a small tree (about 3" diameter)without failing, because in a battle it would slash against helmets, plate armour, other swords and also cut through bone. |

No. *Axes* are for chopping trees. You don't use a gun as a hammer, nor a spoon as a chisel. And in battle, you don't bother trying to hit someone in the helmet or armor with a sword, you hit them where there is *no* metal. Bone, yes, but a decent iron sword can handle that.

| Quote: | | Due to all these reasons a iron longsword would be unusable on the medival battlefield. |

Then we won't find any, will we? No one is going into battle with a weapon that won't work.

| Quote: | | Maybe I understood my Mate wrongly, and he was refering to the amount of swordsmiths compared to the number of standard blacksmiths. |

Could be! But there are some VERY odd ideas out there...

Matthew

|

|

|

|

|

Markus Fischer

|

Posted: Sat 25 Jul, 2020 1:07 pm Post subject: Posted: Sat 25 Jul, 2020 1:07 pm Post subject: |

|

|

Well, maybe these finds are swords that were not intended to be used as a weapon, but rather as a status symbol and an artwork. Annother possibility is, that it was simply a poor-mans sword, who couldnt afford an expensive sword made from fine steel.

Of course a sword is not an axe, but you definitely WILL hit steel in battle (and if it's "just" your opponents blade) a hard strike, edge on flat, from a powerful warrior will definitely bend your blade.

And a cut in to your opponents body that was poorly performed (which will happen in the heat of the fight) WILL bend your blade.

Ive seen a Japanese katana bend from cutting tatami, because the edge inlinement was very of.....yes..... that's quite substantial. And I think that the unhardened spine of a katana is comparable to iron.

To conclude I think that iron is definitely much worse than hardened steel, but I also think that it is not so bad, that it can't be used at all.

When you have a good cutting technique and a defensive fighting style, that relies on quick, short attacks without many exchanges, it is possible to fight with an ironsword without too much trouble.

But the question is: Y tho?

When you can't afford a steel longsword....get an axe...or a Speer.

There is no reason to fight with a sword type that (because of its physique and fighting style) wasn't intended to be made from iron.

|

|

|

|

|

Graham Shearlaw

|

Posted: Mon 27 Jul, 2020 12:09 pm Post subject: Posted: Mon 27 Jul, 2020 12:09 pm Post subject: |

|

|

Really i think people put to much stock in to the metal of swords, there job is to not fail in combat and it being sharpish is secondary.

The tales of swords bending to the level were it impends a fighter are a myth, from an old Roman pre battle prep speech.

A lot of finds have only a cursory examination of the grain microstructure or metal content and there a general trend to call anything that got a carbon content of text book rage 0.6 to 2.0% carbon as High-carbon steel.

Given that anything thing that's corroded has likey lost any working edge it might of had, an things like any case-hardened layer are long gone.

|

|

|

|

Paul Hansen

|

Posted: Tue 28 Jul, 2020 12:02 pm Post subject: Posted: Tue 28 Jul, 2020 12:02 pm Post subject: |

|

|

| Markus Fischer wrote: | To conclude I think that iron is definitely much worse than hardened steel, but I also think that it is not so bad, that it can't be used at all.

When you have a good cutting technique and a defensive fighting style, that relies on quick, short attacks without many exchanges, it is possible to fight with an ironsword without too much trouble.

But the question is: Y tho?

When you can't afford a steel longsword....get an axe...or a Speer.

There is no reason to fight with a sword type that (because of its physique and fighting style) wasn't intended to be made from iron. |

I think that, although quality obviously varied, there seems (from the studies I saw) no apparent correlation between price and quality. For instance, good and bad swords existed in both well made and highly decorated examples and in plain ones.

But we modern people are used to modern steels which perform exactly according to the specification. The idea of a sword failing or not doing what it's supposed to means it was "a wallhanger" or "poorly made in China/India/Pakistan", vs. good swords from reputable makers which always perform exactly as advertised.

In pre-industrial times were was obviously a lot of variation and it seems like people were fine with that.

Also we need to consider the time period which we are discussing. Metallurgy in the early iron age was not the same as in the late middle ages.

| Graham Shearlaw wrote: | A lot of finds have only a cursory examination of the grain microstructure or metal content and there a general trend to call anything that got a carbon content of text book rage 0.6 to 2.0% carbon as High-carbon steel.

Given that anything thing that's corroded has likey lost any working edge it might of had, an things like any case-hardened layer are long gone. |

In the Klingenmuseum in Solingen they have a couple of swords, which were polished by a Japanese trained sword polisher. The sax has a very nice and visible hamon. All these blades seem to be in perfectly usable condition.

Attachment: 130.32 KB Attachment: 130.32 KB

[ Download ]

Attachment: 130.21 KB Attachment: 130.21 KB

[ Download ]

Attachment: 159.8 KB Attachment: 159.8 KB

[ Download ]

Attachment: 133.74 KB Attachment: 133.74 KB

[ Download ]

Attachment: 109.54 KB Attachment: 109.54 KB

[ Download ]

Attachment: 207.77 KB Attachment: 207.77 KB

[ Download ]

Attachment: 126.29 KB Attachment: 126.29 KB

[ Download ]

Attachment: 142.03 KB Attachment: 142.03 KB

[ Download ]

|

|

|

|

|

Alex Ren

|

Posted: Thu 30 Jul, 2020 8:57 am Post subject: Posted: Thu 30 Jul, 2020 8:57 am Post subject: |

|

|

3% is a very specific number. Did the person who said this have some kind of source? Not that I like to assume but I expect there is no historical source(s) that support this statement. I wouldn't be surprised if they were just repeating what they heard from some pseudo-documentary from Youtube or the History Channel.

I'm no expert but don't some other metal items besides swords need to be heat treated and/or tempered? Some types of armor as well as some tools? I don't have a source for this but if I had to guess, then I'd expect the majority of metal workers, not just sword smiths, would know how to do heat treatments and tempering.

|

|

|

|

Jean Henri Chandler

|

Posted: Fri 07 Aug, 2020 8:05 am Post subject: Posted: Fri 07 Aug, 2020 8:05 am Post subject: |

|

|

Somehow it seems the notion of a blacksmith, the same guy who makes nails and horseshoes for the village, hammering away over a campfire making a sword from scratch so to speak is very persistent. It doesn't seem to exist in the late medieval context certainly, and probably not for a long time before that. Making swords was much more of an industrial (or industrial-artisan) process by the time something like longswords existed. Swords were not made one at a time but in large batches ranging from a dozen or so to several hundred or thousand.

I can't speak for the whole of Europe or the entirety of history, but I'm pretty familiar with this for the late medieval and first part of the Early Modern period in Central Europe.

A couple of general points from the point of view of Central Europe:

1) It depends what time period you are referring to. Swords as a technology were somewhat uneven outside of certain centers prior to the 11th Century. By the 15th Century sword making was a thoroughly established craft.

2) If you couldn't fairly good quality steel in large quantities you couldn't make things like heat treated metal armor, which we know they did make (specializing in metalworking centers like Augsburg and Nuremberg).

3) Swordmaking was an organized craft typically managed by craft guilds, 'werk' to the Germans or "corporations" to use the American scholarly term.

4) These craft guilds had regular inspections and tests for quality, especially for export industries, both by the craft organization itself and by the city. All of this is well documented.

5) The swordsmith him or herself didn't typically do the heat treatment of the blade. This was done by other specialists in metallurgy. In some towns like Nuremberg the production of the various grades of iron or steel were mostly done outside of town in partially automated mills, like this wire-pulling mill depicted by Albrecht Dürer...

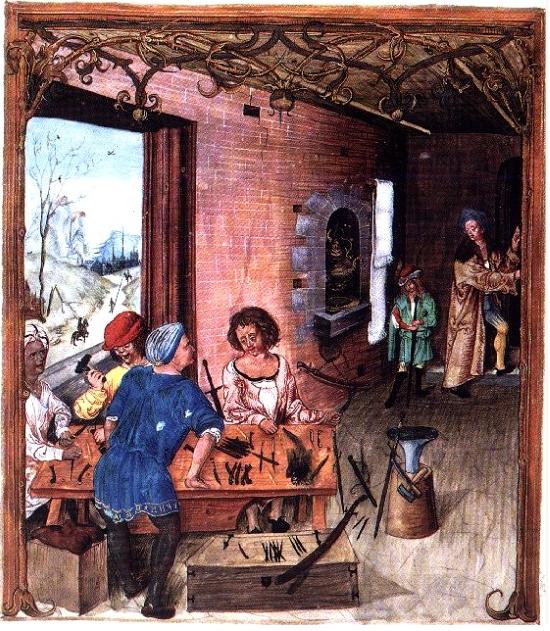

This is a depiction of the inside of a facility like that, from the late 15th Century Von Wolfegg Housebook

Metal billets would be brought from places like that into the city for the more skilled (craft artisan) labor to work with. This too would be subdivided, with the main contractor, usually a member of the cutlers guild, handling overall design and assembly, and subcontracting to blade makers, a specialist of the heat treatments, sword sharpeners, sword polishers, hilt makers, and scabbard makers. Each workshop run by a master artisan supervising multiple journeymen, apprentices, and family members. Again, this is all very well documented in quite a bit of detail, there are dozens of articles on JSTOR and the like, and you also have several period manuscripts or books of craft regulations such as the 1505 Balthasar Behem Codex from Krakow. Here is a depiction of a cutlers workshop from that book:

The housebook of the 12 Brothers of Nuremberg has depictions of workshops of two different types of cutlers (messerer and messerschmeid) of which you can see an example of the former here (famously with the Lion of St. Mark in the background)

https://hausbuecher.nuernberg.de/75-Amb-2-279-14-r/large

and the latter here

https://hausbuecher.nuernberg.de/75-Amb-2-279-35-r/large

Not the latter has the automated forge running, while the former is focused more on final assembly.

Books and games on Medieval Europe Codex Integrum

Codex Guide to the Medieval Baltic Now available in print

|

|

|

|

Jean Henri Chandler

|

Posted: Fri 07 Aug, 2020 8:42 am Post subject: Posted: Fri 07 Aug, 2020 8:42 am Post subject: |

|

|

| Matthew Amt wrote: | My gut reaction is "hogwash". It's like saying most peasants didn't know how to grow crops or raise chickens, or didn't have the tools to run a farm. You don't GET to be a swordsmith unless you know how to MAKE SWORDS. Period. If you show such little promise as an apprentice, you'll be working the bellows until you die of old age. If you have not tools, you can't set up shop and make swords.

Now, were the techniques for making and hardening steel closely guarded secrets? Sure! Secrets passed from one master to his students, so they could be masters in their turn. Obviously without the microscopic knowledge we have today, it was more of an art than a science, and it seems pretty clear that some swords were better than others. But 3%? I seriously doubt it. Unless someone can show that 97% of surviving swords had no steel. |

In the High or Late medieval context, these things wouldn't remain secrets for very long, in large part due to the circulation of journeyman. There have been a few articles for example (in a metalworking context) on how the technology of the draw plate for pulling wire, and the iron vise spread throughout Europe very rapidly due to journeymen and to lesser extent master artisans roaming from town to town. Other technologies like the printing press, the design of Caravel and Carrack type oceangoing ships, and the various techniques for the manufacture of eyeglasses spread in a similar manner.

| Quote: |

Swords in ancient Greek and Roman times were frequently iron, and they worked fine. And I *have* heard that there were still plenty of iron swords well into the middle ages. Though one caveat I would add is that it was apparently common for archeologists in the 19th and early 20th centuries to use *annealing* as a method for conserving and stabilizing excavated iron objects, including swords, which of course destroys all trace of how the sword may have been heat-treated originally. Not to mention weapons that may have been on funeral pyres or in burned buildings. |

Wow, very interesting Matt, I didn't know they did that, it's kind of horrifying though perhaps understandable at the time. It's definitely something to keep in mind for excavated blades.

| Quote: |

Final note, iron is not lead. It won't just fold up under a normal battlefield blow. If you try to cut down a tree with it, yes, that will be bad, but even good swords are not meant for cutting wood. You *can* make reasonable weapons and armor from plain iron, and it was done quite often in ancient and medieval times.

Matthew |

I think one other important distinction between Classical and Early medieval vs. High or Late medieval weapons is that defense, or parrying was mostly done with a shield in the earlier periods, whereas later in Latinized Europe on the sword is not only usually longer but expected to be used for active defense as well as offense. So it needs to be a bit stronger.

J

Books and games on Medieval Europe Codex Integrum

Codex Guide to the Medieval Baltic Now available in print

|

|

|

|

|

Matthew Amt

|

Posted: Fri 07 Aug, 2020 3:07 pm Post subject: Posted: Fri 07 Aug, 2020 3:07 pm Post subject: |

|

|

| Jean Henri Chandler wrote: |

In the High or Late medieval context, these things wouldn't remain secrets for very long, in large part due to the circulation of journeyman. There have been a few articles for example (in a metalworking context) on how the technology of the draw plate for pulling wire, and the iron vise spread throughout Europe very rapidly due to journeymen and to lesser extent master artisans roaming from town to town. Other technologies like the printing press, the design of Caravel and Carrack type oceangoing ships, and the various techniques for the manufacture of eyeglasses spread in a similar manner. |

Thanks, that all makes sense. I just don't know how much mixing there was in the pre-medieval world, or how much was controlled in an organized way--how far back do guilds go? But just from the variation I've seen in artifacts, it just looks like things weren't quite "homogenized", yet, if you get my meaning. Though that's largely on a microscopic level, of course, with outward appearances being strikingly consistent and heavily fashion-driven.

And Thank You for the rest of your excellent posts!! Great stuff. The point about swords being an industrial product is worth repeating and emphasizing--as you say, we tend to have the image of Conan's father stuck in our minds, one guy making one brilliant sword, or modern craftsmen doing commissions one at a time, from start to finish. We live in a very different world!

Matthew

|

|

|

|

Paul Hansen

|

Posted: Sat 08 Aug, 2020 10:41 am Post subject: Posted: Sat 08 Aug, 2020 10:41 am Post subject: |

|

|

Great posts Jean and Matthew!

With regards to guild history, the Romans already had a more or less similar concept, the Collegiae. Whether that was an inspiration for

As per the German Wikipedia, the oldest documented guild is the Frankfurter Fishermen and Skippers Guild established in 945. https://de.wikipedia.org/wiki/Zunft

But I think generally we can say that guilds really became important in the 12th / 13th Century, at least in the Netherlands.

With regards to earlier (8th - 12th C?) sword production, it is thought the monasteries may have played an important role in industrialising sword production.

|

|

|

|

Jean Henri Chandler

|

Posted: Sun 09 Aug, 2020 11:25 am Post subject: Posted: Sun 09 Aug, 2020 11:25 am Post subject: |

|

|

Medieval Craft and merchant guilds are somewhat distinct from Roman collegia or the Greek mystery cults (some of which were associated with crafts, from what I understand) and other similar phenomena in Egypt, Persia and Mesopotamia in that the medieval crafts were made up of people who weren't related or even necessarily from the same region, (partly because they had this roaming journeymen thing), among a few other distinctions. But there were certainly similarities. Most scholars assume that the systems are somewhat distinct because the guilds appeared north of the Alps in several areas including some beyond the zones of former Roman control, though that doesn't prove anything definitively.

I believe in terms of their openness and sharing of technology the Latinized medieval crafts and guilds were somewhat unique historically.

There are some hints of craft guilds in the more urbanized areas of Italy, Langue' Doc, Flanders, and the Rhineland as early as the 7th or 8th Century, but we don't know what those really were. It's just a few lines in some merovingian capitualaties or Papal bulls which can be interpreted a variety of ways. The first formal guild charters that we know of for sure started in the early 12th Century. The watermen of Worms were chartered in 1106 AD. The shoemakers of Würzburg received their charter in 1112; the weavers of Cologne, in 1149, and the shoemakers of Magdeburg, in 1158. It was in the 12th-13th Century that craft guilds in particular seem to have to begun wielding some genuine political power.

If I remember correctly Peter Johnsson has stated that he noticed the significant changes in sword design starting around the 12th Century which may or may not be related.

As for the monasteries, the Cistercian monks in particular were key in the spread of several technologies especially (though not only) those linked to the overshot water wheel of which they were great evangelists, including (eventually) the Catalan Forge and the Barcelona hammer. Both of which were closely associated with industrialized craft metal working industries in all the more urbanized zones of Europe, including (for Central Europe) Swabia, the Rhineland, Flanders, Prussia, Bohemia and the Baltic Sea coast.

J

Books and games on Medieval Europe Codex Integrum

Codex Guide to the Medieval Baltic Now available in print

|

|

|

|

Jean Henri Chandler

|

Posted: Mon 10 Aug, 2020 10:45 am Post subject: Posted: Mon 10 Aug, 2020 10:45 am Post subject: |

|

|

I should add that merchant's guilds appear in the records a bit earlier, late Carolingian era, but that doesn't really reflect on swordmaking. Arab / Hebrew explorers like Ibrahim ibn Ya’qub described what sound like merchant guilds in Germany and Bohemia as early as the 10th Century. Some Carolingian capitularies mention them from the 9th Century.

This capitulary from the 8th Century attempted to ban the insurance associations which were the precursor of merchants guilds (from 779 of the Common Era):

"Let no one dare to take the oath by which people are wont to form guilds. Whatever may be the conditions which have been agreed upon, let no one bind himself by oaths concerning the payment of contributions in case of fire or shipwreck."

The Church and princes were initially very opposed to guilds and the closely associated commune movement, but especially craft guilds. This is a fairly typical comment from the 12th Century by the Benedictine chronicler Guibert of Nogent, (1115 CE)

"The Commune, is an oath of mutual aid (mutui adjutorii conjuratio). A new and detestable word. Through it the serfs

(capite sensi) are freed from all serfdom; through it they can only be condemned to a legally determined fine for breaches

of the law; through it, they cease to be liable to payments which the serfs always used to pay.”

Guild oaths were called "Conjurations" and there were several attempts to outlaw them, as late as the 14th Century Golden Bull of Emperor Charles IV (1356) specifically banned "conjurations, confederations and conspirationes", though it didn't work either. In the same manuscript he granted exceptions to several existing cities that had given him money, like Prague.

Books and games on Medieval Europe Codex Integrum

Codex Guide to the Medieval Baltic Now available in print

|

|

|

|

|

|

You cannot post new topics in this forum

You cannot reply to topics in this forum

You cannot edit your posts in this forum

You cannot delete your posts in this forum

You cannot vote in polls in this forum

You cannot attach files in this forum

You can download files in this forum

|

All contents © Copyright 2003-2026 myArmoury.com — All rights reserved

Discussion forums powered by phpBB © The phpBB Group

Switch to the Basic Low-bandwidth Version of the forum

|