| myArmoury.com is now completely member-supported. Please contribute to our efforts with a donation. Your donations will go towards updating our site, modernizing it, and keeping it viable long-term.

Last 10 Donors: Piotr H. Feret, Graham Shearlaw, Anonymous, Daniel Sullivan, Chad Arnow, Jonathan Dean, M. Oroszlany, Sam Arwas, Barry C. Hutchins, Dan Kary (View All Donors) |

| Author |

Message |

|

Markus Fischer

|

Posted: Sat 06 Jun, 2020 2:20 am Post subject: Shallow hardening of bloom steel Posted: Sat 06 Jun, 2020 2:20 am Post subject: Shallow hardening of bloom steel |

|

|

A while ago I saw a video of a Smith named Ilya Alekseyev who said that historical european swords were not flexible, because the steel they had at the time is shallow hardening, which means that only the outor layer, that is directly contacted with the quenching medium gets hard, but the core remains soft.

That would mean that all European swords have a hamon like the katana, but on the inside...how true is this statement and how much would it affect the flexibility of a blade?

|

|

|

|

Dan Howard

|

Posted: Sat 06 Jun, 2020 5:05 am Post subject: Posted: Sat 06 Jun, 2020 5:05 am Post subject: |

|

|

Not all katanas were made like this. Not all European swords were made like this.

We have extant examples of Celtic La Tene spring steel swords that date before the Roman period.

You won't get any useful answers unless you get a lot more specific with your questions.

Author: Bronze Age Military Equipment, Pen and Sword Books

|

|

|

|

|

Jeremy V. Krause

|

Posted: Sat 06 Jun, 2020 6:19 am Post subject: Posted: Sat 06 Jun, 2020 6:19 am Post subject: |

|

|

Many European swords of the 11th, 12th, and 13th. C. were made with an iron core and steely edge welded on. Not all but some.

I have a sword made with a low carbon core and higher carbon edge and it is quite flexible.

|

|

|

|

|

Markus Fischer

|

Posted: Sat 06 Jun, 2020 7:11 am Post subject: Posted: Sat 06 Jun, 2020 7:11 am Post subject: |

|

|

I think you understood me wrong. I wasn't talking about deferential hardening like it's done on katanas or a iron-steel combination.

What I mean is the following: The normal steel, that was made in these times out of iron ore is different to the steel we use today. One of the differences is, that when you fully quench the blade in oil or water, only the the surface of the steel gets hard, so only the material, that has direct contact to the water/oil. Normal steel, that we use on modern reproductions would harden completely through while the same procedure is used.

(That's at least what the Smith said)

That meant, that EVERY sword at this time had a soft core, simply because the steel of the time behaved like this.

My question is, whether you know if this is true, and how much of flexibility a blade would loose.

I think only Craftsman can say this.

|

|

|

|

|

Tyler C.

|

Posted: Sat 06 Jun, 2020 8:02 am Post subject: Posted: Sat 06 Jun, 2020 8:02 am Post subject: |

|

|

It's not so much ancient steel that is shallow hardening, but plain carbon steel that is shallow hardening. Any plain carbon steel such as any of the 10XX series steels is shallow hardening. That being said, in plain carbon steel, the hardening depth is still around 2mm, (coming from both sides) so it would only be the centers of the very thickets parts of the blade that would not be hardened. The same would be true for a Japanese blade (they used plain carbon steel), but the end of the hamon is usually before the blade is thick enough to worry about that.

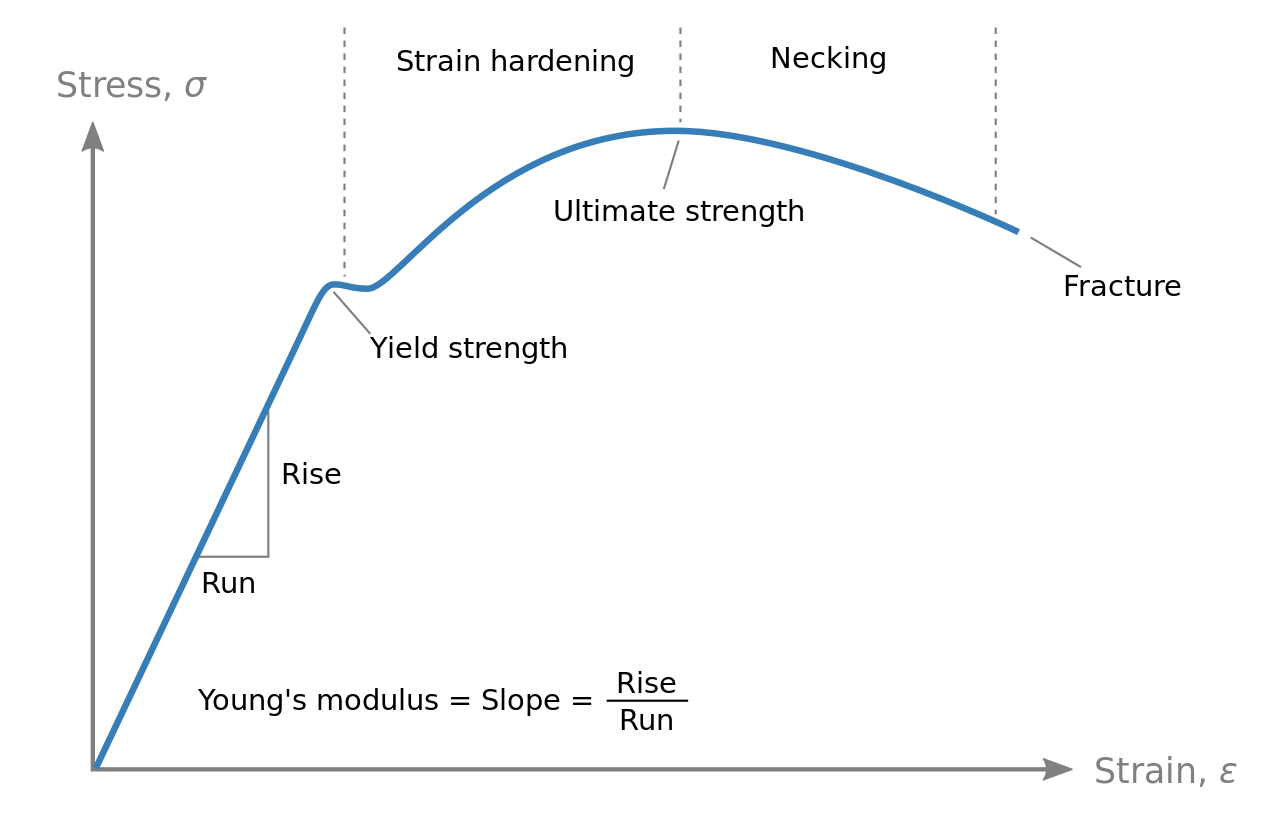

Regarding stiffness/flexibility of a blade, the elastic modulus of steel does not not change when it is hardened. It is only the yield strength that will change. In other words, hardened steel will be just as flexible as unhardened steel, but you will be able to bend it much further and have it spring back to its original shape. For unhardened steel, it will take just as much force to bend (same stiffness), but you will not be able to bend it as far before you see plastic deformation (says bent).

Regarding the modern steels that are often used in reproduction swords, yes, they are often made out of steels that are more readily hardened and as a result they can be hardened all the way through. Hardening is time sensitive, and in plain carbon steel you need to cool the steel very quickly to achieve a martensitic structure (hardened). In the core of the steel the cooling rate is not high enough and instead the steel will transform into a pearlitic structure (soft). the addition of molybdenum to steel stabilizes the martensitic structure and gives it more time to form so you can get deep hardening of the steel.

|

|

|

|

|

Markus Fischer

|

Posted: Sat 06 Jun, 2020 8:18 am Post subject: Posted: Sat 06 Jun, 2020 8:18 am Post subject: |

|

|

Nice explanation. So in short words every plain carbon steel is shallow hardening because it has to be cooled of very fast. I think considering that the hardening depth is 2mm (as you mentioned) it will not be less flexible (it will return to it's original shape after it got flexed), because at the base of the blade the standard thickness might be 6mm, which means that only 1/3 of the blade is actually soft. And in the tapered part of the blade further to the tip it will be hardened completely through, as the thickness is 4mm or lower.

But there is one thing I disagree, namely that the 10XX series is plain carbon steel. There are up to 1,5% of different metals in there. In fact are 1060 and 5160 (spring steel) almost entirely the same steel. They have next to no variation.

|

|

|

|

|

Tyler C.

|

Posted: Sat 06 Jun, 2020 9:46 am Post subject: Posted: Sat 06 Jun, 2020 9:46 am Post subject: |

|

|

5160 is similar to 1060 but with the addition of Cr and Si. For 5160 it’s the addition of Cr and Si that aid in the formation of martensite and help make it more hardenable or deeper hardening.

One correction to my last post. Certain elements like Cr, Si, Mo, V etc. actually stabilize ferrite (not martensite) which in turn makes it easier for martensite to form.

|

|

|

|

|

Markus Fischer

|

Posted: Sat 06 Jun, 2020 9:59 am Post subject: Posted: Sat 06 Jun, 2020 9:59 am Post subject: |

|

|

|

How do you know the hardening depth by the way? Did you break a blade and dipped it in ferric cloride?

|

|

|

|

|

Tyler C.

|

Posted: Sat 06 Jun, 2020 10:10 am Post subject: Posted: Sat 06 Jun, 2020 10:10 am Post subject: |

|

|

| Markus Fischer wrote: | | How do you know the hardening depth by the way? Did you break a blade and dipped it in ferric cloride? |

It is a published value, but I frequently do tests on the steels that I use when smithing. I do it by drawing out a piece of steel that is about 5X10mm then hardening, then drawing the temper from one side and breaking it bit at a time from the full hard end. Even with the 5mm thickness I get full hardening. This it likely because it’s such a small piece that there is not a lot of thermal mass. I think with a blade you would get an unhardened core.

|

|

|

|

|

Keith S.

|

Posted: Thu 16 Jul, 2020 5:59 pm Post subject: Posted: Thu 16 Jul, 2020 5:59 pm Post subject: |

|

|

|

The flexibility of a blade has more to do with what happens after quenching than the quench itself. As long as the blade has enough carbon to be called steel and form martensite in the quench, then it can be tempered to relieve stress and introduce "springiness". The core of the blade does not need to have the same amount of yield strength "or springiness" as the surface of the blade because core won't need to flex as much as the outside surface.

|

|

|

|

|

Keith S.

|

|

|

|

|

Tyler C.

|

Posted: Thu 16 Jul, 2020 6:55 pm Post subject: Posted: Thu 16 Jul, 2020 6:55 pm Post subject: |

|

|

You are right. There is a difference but it is very small, and it is in the opposite direction you would think i.e. hardened steel is actually less stiff than unhardened steel. The important difference is in the yield strength which is much higher in hardened steel allowing the blade to bend further and then spring back to the original shape.

|

|

|

|

|

Pieter B.

|

Posted: Fri 17 Jul, 2020 7:16 am Post subject: Posted: Fri 17 Jul, 2020 7:16 am Post subject: |

|

|

An account from the monastery of St. Gall mentions Emperor Louis bending the tip of a blade back to the base/hilt. One of the swords handed to him by a northmen snapped before this was accomplished but the other held and returned to shape.

An 11th century Persian work tells of the blades of the Rus which could be bent double and would still return to shape. Nasir al-Din al-Tusi in the 13th century said the same about Frankish swords.

To the best of my knowledge swords like the Solingen and Toledo ones were made with iron cores/hilts well up until the 19th century.

I'd be really surprised if having a lower hardness core made any difference.

|

|

|

|

Paul Hansen

|

Posted: Sun 19 Jul, 2020 11:49 pm Post subject: Posted: Sun 19 Jul, 2020 11:49 pm Post subject: |

|

|

| Pieter B. wrote: | An account from the monastery of St. Gall mentions Emperor Louis bending the tip of a blade back to the base/hilt. One of the swords handed to him by a northmen snapped before this was accomplished but the other held and returned to shape.

An 11th century Persian work tells of the blades of the Rus which could be bent double and would still return to shape. Nasir al-Din al-Tusi in the 13th century said the same about Frankish swords.

To the best of my knowledge swords like the Solingen and Toledo ones were made with iron cores/hilts well up until the 19th century.

I'd be really surprised if having a lower hardness core made any difference. |

Those statements seem contradictory.

A steel has a yield strength and a ultimate tensile strength:

https://en.wikipedia.org/wiki/Stress%E2%80%93strain_curve

If a steel is stressed beyond it's yield strength, it stays bent after removing the force.

If a steel is stressed beyond it's tensile strength, it breaks.

So if you bend a sword and it breaks, it is stressed beyong it's tensile strength.

If it stays bent, you stressed it to a point between the yield and tensile strength.

Hardness and yield strength are directly proportionate to each other.

https://en.wikipedia.org/wiki/Rockwell_scale

This means that if you have a sword witth an unhardened, plain iron core ( the fuller area) with hardened steel edges, such a sword is still likely to take a bend or break in combat. Such a sword would not be flexible enough to bend double and return to true, as indicated by your sources. This means that, at least the swords mentioned in those sources, were made of through hardened steel. What we don't know from such texts, is whether these were the exceptions or the norm.

Back to the OP: "historical European swords are not flexible because of the steel used", several studies focussing on different regions and periods (e.g. Radomir Pleiner on La Tene swords and Ann Feuerback on Migration Age Steppe swords) show a very large variance in hardness and crystalline structures. So I think the obvious answer is that every time and place had both very good and very bad swords. It may also indicate that the smiths had difficulty controlling the process and may turn out good and bad swords.

|

|

|

|

|

Pieter B.

|

Posted: Mon 20 Jul, 2020 7:35 am Post subject: Posted: Mon 20 Jul, 2020 7:35 am Post subject: |

|

|

|

From what I gather the swords did not just have steel edges but also a layer of steel on the fuller/flat. Steel on the outside, iron on the inside.

|

|

|

|

|

Keith S.

|

Posted: Tue 21 Jul, 2020 8:23 pm Post subject: Posted: Tue 21 Jul, 2020 8:23 pm Post subject: |

|

|

| Tyler C. wrote: |

You are right. There is a difference but it is very small, and it is in the opposite direction you would think i.e. hardened steel is actually less stiff than unhardened steel. The important difference is in the yield strength which is much higher in hardened steel allowing the blade to bend further and then spring back to the original shape. |

Yes, the difference in yield strength between tempered steel and annealed steel is very large, and while the annealed steel has a slight edge in young's modulus, it should be fairly inconsequential in most contexts.

|

|

|

|

|

Keith S.

|

Posted: Tue 21 Jul, 2020 8:32 pm Post subject: Posted: Tue 21 Jul, 2020 8:32 pm Post subject: |

|

|

| Paul Hansen wrote: |

This means that if you have a sword witth an unhardened, plain iron core ( the fuller area) with hardened steel edges, such a sword is still likely to take a bend or break in combat. Such a sword would not be flexible enough to bend double and return to true, as indicated by your sources. This means that, at least the swords mentioned in those sources, were made of through hardened steel. What we don't know from such texts, is whether these were the exceptions or the norm.

|

I am no smith, so this may seem like a silly question, but how is through hardening achieved? Doesn't quenching the steel mostly effect the surface of the blade and leaves the core relatively soft. How would one quench harden the blade all the way through and another quench fail to do so?

|

|

|

|

Paul Hansen

|

|

|

|

|

Tyler C.

|

Posted: Mon 27 Jul, 2020 8:33 pm Post subject: Posted: Mon 27 Jul, 2020 8:33 pm Post subject: |

|

|

| Keith S. wrote: | | I am no smith, so this may seem like a silly question, but how is through hardening achieved? Doesn't quenching the steel mostly effect the surface of the blade and leaves the core relatively soft. How would one quench harden the blade all the way through and another quench fail to do so? |

Keith,

I wanted to shed some more light in addition to Paul's statements above. For steel it's all about timing. With plain carbon steels you have approximately 1 second to cool the steel from the upper critical temperature (~800°C) to the martensite start temperature (~300°C). Any portion of the steel mass that does not cool quickly enough will not be hardened. This is why the core steel in thicker areas will not be hardened. As you can imagine there are many things that can affect your cooling rates. Anvils, for example, are cooled under falling water to increase the cooling rate and eliminate the chance of uneven cooling from steam pockets on the surface. Movement of the work piece or movement of the water can make a big difference. The temperature of the water will also have an effect, and even variables like adding salt to the water will change cooling rates. In addition to this there is also a chance that the smith did not precisely hit the upper critical temperature. If the blade is slightly too hot it will preheat the water directly around the blade and again change the cooling rate during the range where it matters (800-300°C).

Now once you start adding alloying elements to the steel it changes the time you have to cool the steel and the temperature range required to achieve hardening. With 5160 for example you have something like 4 seconds to cool from ~750-~250°C. The temperature drop is pretty close (my numbers are not exact), but the time you have is ages compared to plain carbon steel. There will obviously still be a limit to the hardening depth that you can achieve, but it will be much thicker than plain carbon steel. Certainly anything close to the thickness of a sword will be easy to through harden with an alloy like 5160.

| Paul Hansen wrote: |

This means that if you have a sword witth an unhardened, plain iron core ( the fuller area) with hardened steel edges, such a sword is still likely to take a bend or break in combat. Such a sword would not be flexible enough to bend double and return to true, as indicated by your sources. This means that, at least the swords mentioned in those sources, were made of through hardened steel. What we don't know from such texts, is whether these were the exceptions or the norm. |

Now all that being said, this question really goes back to Paul's statement earlier (above). My initial guess would be that the claim of a sword bending in half and returning to strait is an exaggeration. Perhaps they meant that it bent in half and yielded, and then was bent straight again without breaking which would also have been a feat for the steels of the time. Nevertheless, assuming that the account is true it would actually be possible to estimate the yield strength of the steel used with a few assumptions about the geometry. To simplify it even further (perhaps too much) we could assume that the average thickness is ~3mm and that the bend was an even arc (this of course is not likely, but it is the most conservative assumption to keep the radius at a maximum). Based on the time period, the length of the blade is likely not going to be longer than 35in (giving the blade the advantage again). This means the blade would make an arc with a radius or approximately 5.5in. With a 3mm thick blade this will mean that the outer surface stress will be 30,000,000psi X 0.059in / 5.5in = 322,000psi (modulus X distance from neutral axis / radius = stress at surface). Even by today's standards that is a very high yield strength and we have made a bunch of estimates in favor of the sword. Of course if we assume the thickness of the blade is something like 1mm then the stress drops down to more reasonable levels. In my opinion, this statement is either an exaggeration, misunderstood, or the sword referred to was exceptionally thin and specifically designed to be very flexible. My guess is that the statement is misunderstood and it should not be implied that the sword did not yield during the test. Perhaps this bend test was a common test of blade quality and the specifics of the test were implied. Just complete guesses here.

Regarding the statement that this blade would have to be through hardened, I have to disagree somewhat. It is the outermost surfaces of the blade that take the majority of the stress. As you move inward toward the neutral axis the stresses drop considerably. Likely at the point you reach the unhardened core of the blade, the stress will be within the range that can be supported by the unhardened steel/iron without yielding. With all other factors the same a sword with a soft core will function almost identically to a through hardened blade as long as the hardened shell is reasonably thick.

|

|

|

|

Paul Hansen

|

Posted: Tue 28 Jul, 2020 10:31 am Post subject: Posted: Tue 28 Jul, 2020 10:31 am Post subject: |

|

|

| Tyler C. wrote: | | 322,000psi |

That equals 2220 MPa.

For C75 (unalloyed steel, 0.75% C, a common knife steel in Germany), a published tensile strength in quenched and tempered condition is 1900 MPa at 564 HRC.

https://matmatch.com/materials/minfm56065-en-10132-4-grade-c75s-quenched-and-tempered

https://www.thyssenkrupp-steel.com/media/content_1/publikationen/precision_steel/produktinformationen_1/verguetungsstahl/thyssenkrupp_c75_c75s_product_information_precision_steel_en.pdf

As yield stress and hardness are more or less proportional, then that would put the hardness at 60+ HRC if we extrapolate some tables that I quickly found on the internet:

https://media.cheggcdn.com/media/b9b/b9bd1f06-8edc-40bf-8f31-bd156ff10be3/phpv4SBPS.png

https://varmintal.net/rc-curve.png

So that means the story is not that likely, even with modern steels.

So I agree with your assessment that it meant the sword was able to be bent back to true instead of breaking.

| Tyler C. wrote: | | Regarding the statement that this blade would have to be through hardened, I have to disagree somewhat. It is the outermost surfaces of the blade that take the majority of the stress. As you move inward toward the neutral axis the stresses drop considerably. Likely at the point you reach the unhardened core of the blade, the stress will be within the range that can be supported by the unhardened steel/iron without yielding. With all other factors the same a sword with a soft core will function almost identically to a through hardened blade as long as the hardened shell is reasonably thick. |

I didn't calculate anything (too lazy...  ) but I guess it does depend on the yield strength of the core and on the stress levels on the surface and at the core. The problem I was thinking about was if the core exceeds the yield strength while the surface is still elastic. I think in that case, the sword would still take a bend. ) but I guess it does depend on the yield strength of the core and on the stress levels on the surface and at the core. The problem I was thinking about was if the core exceeds the yield strength while the surface is still elastic. I think in that case, the sword would still take a bend.

But if we assume that the sword will exceed the yield strength anyway, then I think it doesn't matter than much. The core is unlikely to exceed the ultimate strength while the surface is still in the elastic range.

Also I think calculating sword strength is a bit complicated if we consider pattern welding and welded-on steel edges, as well as hardening thickness.

|

|

|

|

|

|

You cannot post new topics in this forum

You cannot reply to topics in this forum

You cannot edit your posts in this forum

You cannot delete your posts in this forum

You cannot vote in polls in this forum

You cannot attach files in this forum

You can download files in this forum

|

All contents © Copyright 2003-2026 myArmoury.com — All rights reserved

Discussion forums powered by phpBB © The phpBB Group

Switch to the Basic Low-bandwidth Version of the forum

|