| Author |

Message |

|

Nat Lamb

|

Posted: Mon 12 Mar, 2012 10:15 pm Post subject: Advice from test-cutters and blade makers sought Posted: Mon 12 Mar, 2012 10:15 pm Post subject: Advice from test-cutters and blade makers sought |

|

|

I hope I am posting this in the right section, appologies if I have not

I am after a bit of advice from those more knowledgeable about matters of blade profile and cutting. Without getting too technical about minutia, what would you regard as the minimum width of a blade, at what distance from the tip, for a sword to be an “effective” cutter. I am in particular thinking of a hexagonal blade section, and more interested in swords used in two hands, but any insights gladly welcomed.

I do not necessarily mean “the best cutter against all medium, ever” just one that can still be used effectively for shearing/cutting blows against organic targets. Metric measurements preferred, but not required.

Thoughts?

|

|

|

|

Luka Borscak

|

Posted: Tue 13 Mar, 2012 12:11 am Post subject: Posted: Tue 13 Mar, 2012 12:11 am Post subject: |

|

|

|

Extremely difficult question to answer. I have a Hanwei Tinker Longsword which is quite a narrow blade in the top area of the blade because of its profile taper, but it still cuts very well, but I have to strike the target with a part of blade closer to the middle than when I cut with some other wider swords...

|

|

|

|

|

Herbert Schmidt

|

Posted: Tue 13 Mar, 2012 12:58 am Post subject: Posted: Tue 13 Mar, 2012 12:58 am Post subject: |

|

|

This is almost impossible to answer as the width is the least important aspects in this regard.

Cross section, thickness, edge geometry, sharpness, weight etc are much more important.

In fact, I am in the process of writing a book about this very topic - just to give you an idea that it is not something that can be explained in a few words.

Why is the width so important for you?

Herbert

www.arsgladii.at

Historical European Martial Arts

|

|

|

|

|

Nat Lamb

|

Posted: Tue 13 Mar, 2012 3:31 am Post subject: Posted: Tue 13 Mar, 2012 3:31 am Post subject: |

|

|

Herbert and Luka, thanks for the replies

The basis for my interest in width is that I am an (extremely) amateur sword maker, mostly via stock removal. My past attempts have been for stage combat / re-enactment purposes. I am currently in the “planning” phase of a project, and a poor enough craftsman that more care in the hands-on phase probably won’t make much difference, but more careful planning might. One of the things I have seen people with a bit more cutting experience say is that a given blade is “wide enough to still be a good cutter” which I took to be referring to profile taper.

Essentially I have limited physical resources, but plenty of time and sketchpaper, so trying to get a sword that “looks right” before committing materials. Attempting to emulate late 14th c type XVII that would be suitable for trusting but without being so narrow as to be ineffective in a cut against lightly armoured opponents. Or to put it another way, a sword for use against a man-at-arms in late 14th century harness, but that could still be used for lopping of an uppity peasant’s arm should the opportunity arise (re-enactment character motivation, such violent and classist views are not endorsed by the poster  ). ).

|

|

|

|

|

Josh S

|

Posted: Tue 13 Mar, 2012 8:11 am Post subject: Posted: Tue 13 Mar, 2012 8:11 am Post subject: |

|

|

|

When people refer to a blade's width in that context, they're really making a point about the blade's mass. With any given cross-section of a steel blade, there are only two ways to increase its mass: 1) increase its thickness, or 2) increase its width. Since increasing its thickness will have a larger negative effect on cutting ability due to drag, it is more worthwhile to increase its width instead. But this increase in width is just a way to increase the amount of mass behind the edge, thereby giving it more punch.

|

|

|

|

|

Nat Lamb

|

Posted: Tue 13 Mar, 2012 8:15 am Post subject: Posted: Tue 13 Mar, 2012 8:15 am Post subject: |

|

|

ok, then I will rephrase my question somewhat.

What mass of the end of the blade would you think is the minimum in terms of being an effective cutting sword, in terms of x width at distance y from the tip?

|

|

|

|

|

Herbert Schmidt

|

Posted: Tue 13 Mar, 2012 8:36 am Post subject: Posted: Tue 13 Mar, 2012 8:36 am Post subject: |

|

|

| Nat Lamb wrote: | ok, then I will rephrase my question somewhat.

What mass of the end of the blade would you think is the minimum in terms of being an effective cutting sword, in terms of x width at distance y from the tip? |

I think you still go at it from a wrong angle.

What is your thickness is the important question.

So let's talk about the POP (point of percussion) or very roughly one third from the tip.

What thickness do you have? What blade profile (I think you mentioned hexagonal)?

Then you can start to think about width.

Or in other words: plan the general outline of the sword, then start with the thickness at the cross and how you want to reduce it towards the point. The rest falls in place.

all the best for your project!

Herbert

www.arsgladii.at

Historical European Martial Arts

|

|

|

|

Luka Borscak

|

Posted: Tue 13 Mar, 2012 12:24 pm Post subject: Posted: Tue 13 Mar, 2012 12:24 pm Post subject: |

|

|

The best way is of course to replicate dimensions of a historical specimens you are using for your inspiration.

|

|

|

|

|

Nat Lamb

|

Posted: Tue 13 Mar, 2012 5:45 pm Post subject: Posted: Tue 13 Mar, 2012 5:45 pm Post subject: |

|

|

Ahh, the problem I have is that because I live in Australia, access to historical examples is tricky at best.

The stock I have is 5.2mm thick, which will probably end up being 5mm thick at the base of the blade(A little thin for a type XVII, but best I can do). Assuming a distal taper down to about 3mm near the tip. This means that at the POP you describe that blade will be approxamately 3.7mm thick. So with a flattened hexagonal blade section, what do you think is the narrowest width that will still be effective in cutting?

Or, for a more "rule of thumb" estimate, those who make blades, roughly how wide would you tend to make a sword at 2/3 of blade length for a hexagonal section 14th c style blade?

|

|

|

|

Jean Thibodeau

|

Posted: Wed 14 Mar, 2012 1:31 am Post subject: Posted: Wed 14 Mar, 2012 1:31 am Post subject: |

|

|

| Nat Lamb wrote: | Ahh, the problem I have is that because I live in Australia, access to historical examples is tricky at best.

The stock I have is 5.2mm thick, which will probably end up being 5mm thick at the base of the blade(A little thin for a type XVII, but best I can do). Assuming a distal taper down to about 3mm near the tip. This means that at the POP you describe that blade will be approxamately 3.7mm thick. So with a flattened hexagonal blade section, what do you think is the narrowest width that will still be effective in cutting?

Or, for a more "rule of thumb" estimate, those who make blades, roughly how wide would you tend to make a sword at 2/3 of blade length for a hexagonal section 14th c style blade? |

Purely a guess but 3/4" ( 19 mm) wide at the POP would seem a reasonable minimum leading to a very narrow point maybe 1/4" an inch or two from the point.

Maybe closer to 2 mm distal taper at the tip and 3 mm at the POP. ( Thicker would cut less well, but still cut, but be more rigid for a Type XVII ..... everything is a compromise.   ). ).

You can easily give up your freedom. You have to fight hard to get it back!

|

|

|

|

|

Aleksei Sosnovski

|

Posted: Wed 14 Mar, 2012 2:01 am Post subject: Posted: Wed 14 Mar, 2012 2:01 am Post subject: |

|

|

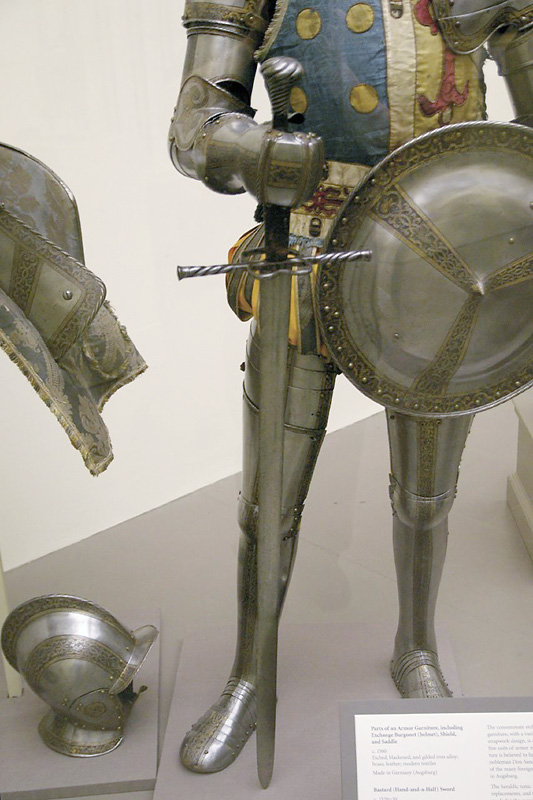

Look at the first sword on this picture

. .

It is about 35mm wide at the widest point tapering to about 18-20mm, maybe even less, at the point. This blade has no distal taper so it is about 5.5-6mm thick. The weight is about 1-1.1kg. Yet at its COP it can easily cut branches over 1" thick and I am absolutely confident that a good cut with this sword to an unarmored part of the body will instantly incapacitate (penetrate the scull, cut leg to the bone, maybe entirely cut off a hand).

If you use stock removal and your steel is already pretty thin (5.5 mm is somewhat thin for a longsword but is perfectly enough) I would suggest 2 options:

1) make a relatively wide mostly cut-oriented longsword like this one

or this one

2) forget about distal taper and make a mostly thrust-oriented sword like this one

or this one

If I chose the former option I would make my blade 35-45mm wide at the hilt tapering to 20-30mm at the point (depending on desired weight and balance and amount of distal taper). If I chose the latter option I would make my blade at least 40mm wide at the hilt (to compensate for the lack of distal taper) and about 15-20mm at the point.

When the blade is finished choose the hilt style that you wish. I would probably go for a scent stopper pommel and S-shaped crossguard because both are easy to make and should look good on such blade.

|

|

|

|

|

Nat Lamb

|

Posted: Wed 14 Mar, 2012 3:54 am Post subject: Posted: Wed 14 Mar, 2012 3:54 am Post subject: |

|

|

Ahh, thankyou!I realise I was probably asking the question in the wrong way, but the various peices of advice are exactly the sort of information I was after, should really help me get this project moving.

Aleksei, do you (or anyone else) have any close up pictures of either of the swords you mention in option 2 of your advice, or swords with similar tip sections?

|

|

|

|

|

Scott Woodruff

|

Posted: Mon 19 Mar, 2012 7:39 am Post subject: Posted: Mon 19 Mar, 2012 7:39 am Post subject: |

|

|

I don't have any pics to show you, but I have had some experience shaping the sort of robust, acute point that you want to do. The trick with these is to maintain your thickness out towards the end of the point. It is very easy to grind the point out too thin as you continue your bevel out to the point, what you need to do is "twist" your bevel or make it more steep as it approaches the point. Another way to describe this is that your section should blend from a flattened rhomboid to almost square in the last few mm. A point like this may compromise your tip-cutting ability, but is necessary to conform to type xvii. With the stock thickness you have, I would suggest that you keep your distal taper to a minimum, if not zero. This will insure that your blade is stiff enough to stay xvii-ish in character. If cutting performance is really important to you, you might consider doing a different type, not that a xvii can't be a completely sufficient cutter. Considering what you seem to want out of your sword, I would suggest that you make the base as wide as you can while still being consistent with the type. A fairly straight-edged taper from 4-4.5 cm would, in my opinion, be ideal. Hope this helps.

Ps- there are some Scandinavian longswords that are like extra-wide XVII's, 5cm plus at base, usually with type 5 guards and wheel pommels. So if you want to make an extra-wide XVII to improve cutting ability, there is a historical precedent.

|

|

|

|

|

Nat Lamb

|

Posted: Thu 05 Apr, 2012 9:50 pm Post subject: Posted: Thu 05 Apr, 2012 9:50 pm Post subject: |

|

|

|

Scott, thanks for the info. The Scandinavian swords you describe sound really interesting, and might well be the direction I take this project in, cheers for the awesome tip!

|

|

|

|

|

Scott Woodruff

|

Posted: Fri 06 Apr, 2012 6:34 am Post subject: Posted: Fri 06 Apr, 2012 6:34 am Post subject: |

|

|

|

I am in the beginning stages of making one of these Scandinavian longswords. In many ways your project and the expectations that you have for it are similar to mine. My piece of material is 8mm thick and over 6cm wide, so I have a little more latitude than you do. Basically, my blade will be like an extra-wide-based XVII or XVIa, going from 5-6cmx8mm at the base to about 3-3.5cmx3-5mm at cop. The blade will only be 32" long, but total length will be 46-48", so a really long grip. Are you sticking to your type XVII idea, or are you considering doing a more cut-oriented type? XVII's are extremely under-represented in the world of replicas, so I would be really excited to see you do one. If you go with the maximum type-consistent width and minimal distal taper, you should be able to make a sufficiently stiff XVII blade with the 5mm material. You really don't need much distal taper to lop limbs off of peasants.

|

|

|

|

|

Tom Kinder

|

Posted: Fri 06 Apr, 2012 9:10 am Post subject: Posted: Fri 06 Apr, 2012 9:10 am Post subject: |

|

|

I too am an extremely novice blade maker but a pretty good cutter and I work with a guy who is a world class blade maker.

I agree with the above that if you really want a good cutting sword you would be well advised to move away from a type XVII.

have no doubt that a XVII could and did wreck heck on unarmored foes but let's face it, we won't be cutting people with our modern swords (at least I hope not). Bamboo, tatami, water bottles and the like are much more common. a type XVII is a brutal sword with typically wide angles on their edge bevels so no matter how sharp they are they don't make nice smooth cuts like modern backyard cutters like. I got to play with Albion's XVII not too long ago and while it was a heck of a fun sword and respectably sharp I couldn't get it through a full roll of tatami. keep in mind that it is probably on the lighter and better cutting end of the XVII spectrum (at least in my opinion for whatever that is worth).

cutting swords are designed with wider blades so that there can be enough steel out in the cutting areas of the sword to keep the blade stable while still allowing a nice thin cross section. it also promoteslong gentle narrow bevels which is a good thing for cutting too. the actual mass of a cutting sword and a thrusting sword (assuming similar sizes and all) are closer to the same amount than it would appear because the cutting sword is thin and wide while the thruster is narrow and thick. they won't be exactly the same but closer than most would expect I bet.

this is where I'm going to diverge from the rest of the pack: distal taper. if you want a sword that really performs well you must have distal taper. a sword without any distal taper tends to handle like a crowbar. I know a lot of people will tell you that type XVII swords are basically crowbars but I don't believe this. yes, they are more rugged and massy than a lot of other sword types but they did have distal taper and a good one will have it. distal taper is hard to do and I don't know how to do it with a grinding set up (at least not reliably) but I have a clue how to forge it in.

in forging anyway, it is my understanding that one of the first things you do with your sword billet is to establish the distal taper and the basic profile taper. after that the rest of the features start to take shape as it gets worked. I suspect that you should do things in this order when grinding too.

the thrust oriented swords tend to have what is called convex distal taper which mean they taper slowly at first then accelerate in the last third of the sword. by contrast, cutting swords tend to taper quickly in the first part of the blade then level out a bit (or progress in steps of thinning and leveling) and then dive to the point at the last second this is called concave distal taper. some swords, most notably katana, have flat distal taper wich means just what it sounds like: the thickness tapers down evenly enough it could make a straight line from one end of the blade to the other.

Convex tapers tend to make a sword stiffer and if they are made a little bit on the wider side of things you can actually provide bevels long and thin enough to make a very good cutter that takes advantage of the characteristic stiffness. Type XVIII swords often fit this description.

as for how much distal taper, that's something you will need to experiment with but I'll say that in my experience 40% distal taper or less is not very much and should make a pretty stiff sword while 60% is typically only seen on cutting swords. some antiques I had heard about have as little as 20% but they all have some. 20% seems to be an extreme example rather than a typical one so if you keep your work in the 35- 60% range you should be able to make decent cutting or thrusting swords as is your desire.

hope this helps, and I hope I haven't gotten something screwy, I'm mostly relaying info I have heard from experienced makers in conversations so I could be twisting it and getting things wrong.

that's my $.02, salt to taste.

|

|

|

|

|

Scott Woodruff

|

Posted: Sat 07 Apr, 2012 8:04 pm Post subject: Posted: Sat 07 Apr, 2012 8:04 pm Post subject: |

|

|

|

Tom, for the most part, everything you said is quite correct. However, a blade with really acute profile taper does not need much distal taper to arrive at a good distribution of mass ( though of course I wouldn't suggest zero, I said "minimum". )Some type XVII's have very little distal taper. If Nat's material were thicker, I would encourage some generous distal taper, but at 5mm, that doesn't leave much leeway. Sure, one could curve the edges, widen the cop and distally taper the blade to improve effectiveness at cutting bottles and such, but then you wouldn't have a type XVII anymore. Nat stated that he wanted a sword that was a good stiff thruster, but still able to cut "organic" targets ( I am assuming flesh.) A hexagonal section blade with straight-edged taper from 4-5cm at the base to an acute point and distal taper from 5mm to 4mm at the point would fit the bill perfectly ( this does follow your at least 20 percent rule incidentally.) I have a sword that has about 40 percent distal taper from 5mm and it is anything but stiff (though to qualify, it has much less profile taper than what we are talking about here and a lenticular section.) I don't think that there is anything "hard" about grinding a blade with distal taper, you just grind more at the point more than you do at the base. When shaping a blade by stock removal, I usually shape my profile taper with an angle grinder, then rough out my distal taper, then rough out my bevels. Then I switch to the belt-sander to finish my bevels and finally refine my distal taper. Last, if the blade is lenticular, I blend everything together. By the way, nice post, you gave us a very concise little summary of the basics of distal taper that I am sure someone will find quite enlightening/useful.

|

|

|

|

|

|

You cannot post new topics in this forum

You cannot reply to topics in this forum

You cannot edit your posts in this forum

You cannot delete your posts in this forum

You cannot vote in polls in this forum

You cannot attach files in this forum

You can download files in this forum

|

All contents © Copyright 2003-2026 myArmoury.com — All rights reserved

Discussion forums powered by phpBB © The phpBB Group

Switch to the Basic Low-bandwidth Version of the forum

|