| The Cutlass is: |

| not a weapon I'm interested in |

|

4% |

[ 6 ] |

| a weapon I would like in my collection |

|

58% |

[ 71 ] |

| not my usual interest but I like this one |

|

36% |

[ 44 ] |

|

| Total Votes : 121 |

|

| Author |

Message |

Ben Potter

Industry Professional

|

Posted: Tue 12 Jan, 2010 12:15 am Post subject: Cutlass work in progress Posted: Tue 12 Jan, 2010 12:15 am Post subject: Cutlass work in progress |

|

|

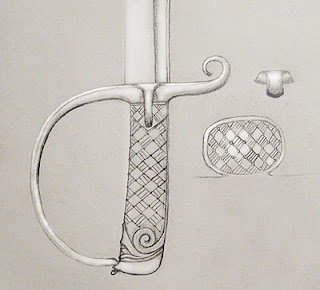

I am documenting the process of making this piece on my blog and thought you might like to see it here as well.

I forged the blade a couple of months ago so this is about crafting the hilt.

Ben Potter Bladesmith

It's not that I would trade my lot

For any other man's,

Nor that I will be ashamed

Of my work torn hands-

For I have chosen the path I tread

Knowing it would be steep,

And I will take the joys thereof

And the consequences reap.

|

|

|

|

Ben Potter

Industry Professional

|

Posted: Tue 12 Jan, 2010 12:21 am Post subject: Posted: Tue 12 Jan, 2010 12:21 am Post subject: |

|

|

Here are the steps so far.

Knuckle bow and thumb-ring after forging:

Thumb-ring after shaping and polishing:

Knuckle-bow in-let for the tang, and rough shaped:

Ben Potter Bladesmith

It's not that I would trade my lot

For any other man's,

Nor that I will be ashamed

Of my work torn hands-

For I have chosen the path I tread

Knowing it would be steep,

And I will take the joys thereof

And the consequences reap.

|

|

|

|

|

Matthew Stagmer

Industry Professional

|

Posted: Tue 12 Jan, 2010 8:28 am Post subject: Posted: Tue 12 Jan, 2010 8:28 am Post subject: |

|

|

Looks great so far. I will be watching this one for sure!

Matthew Stagmer

Maker of custom and production weaponry

Youtube.com/ThatWorks

|

|

|

|

Shahril Dzulkifli

|

Posted: Wed 13 Jan, 2010 3:32 am Post subject: Cutlass work in progress Posted: Wed 13 Jan, 2010 3:32 am Post subject: Cutlass work in progress |

|

|

Ben,

When that cutlass of yours is finished I hope you'll show the pictures.

“You have power over your mind - not outside events. Realize this, and you will find strength”

- Marcus Aurelius

|

|

|

|

Ben Potter

Industry Professional

|

Posted: Wed 13 Jan, 2010 8:21 pm Post subject: Posted: Wed 13 Jan, 2010 8:21 pm Post subject: |

|

|

I finished shaping the knuckle bow and forged the shell guard:

Ben Potter Bladesmith

It's not that I would trade my lot

For any other man's,

Nor that I will be ashamed

Of my work torn hands-

For I have chosen the path I tread

Knowing it would be steep,

And I will take the joys thereof

And the consequences reap.

|

|

|

|

|

Matthew Stagmer

Industry Professional

|

Posted: Thu 14 Jan, 2010 8:43 am Post subject: Posted: Thu 14 Jan, 2010 8:43 am Post subject: |

|

|

Whats the shell forged from? Is it wrought or something?

Matthew Stagmer

Maker of custom and production weaponry

Youtube.com/ThatWorks

|

|

|

|

Ben Potter

Industry Professional

|

Posted: Thu 14 Jan, 2010 9:59 am Post subject: Posted: Thu 14 Jan, 2010 9:59 am Post subject: |

|

|

1018 mild steel, wrought it really hard to get on this side of the country, I'm looking for it but it is elusive.

Also, I thought that the steel would work better for this design,

Ben Potter Bladesmith

It's not that I would trade my lot

For any other man's,

Nor that I will be ashamed

Of my work torn hands-

For I have chosen the path I tread

Knowing it would be steep,

And I will take the joys thereof

And the consequences reap.

|

|

|

|

J Helmes

Industry Professional

|

Posted: Thu 14 Jan, 2010 12:21 pm Post subject: Posted: Thu 14 Jan, 2010 12:21 pm Post subject: |

|

|

nice design ben! I look forward to seeing this one progress.

cheers Jeff

|

|

|

|

|

Martin Murd

|

Posted: Thu 14 Jan, 2010 1:56 pm Post subject: Posted: Thu 14 Jan, 2010 1:56 pm Post subject: |

|

|

Cutlasses are one of my favorite type of swords.Alas, my current financial state does not allow me to buy one and has reduced me to a window-shopper.

Nevertheless... you have an excellent sense of design and function, therefore i'd very much like to see, what will unveil.

Merlon

|

|

|

|

Ben Potter

Industry Professional

|

Posted: Fri 15 Jan, 2010 11:29 pm Post subject: Posted: Fri 15 Jan, 2010 11:29 pm Post subject: |

|

|

Made it back to the shop today for a bit and shaped the shell guard.

Ben Potter Bladesmith

It's not that I would trade my lot

For any other man's,

Nor that I will be ashamed

Of my work torn hands-

For I have chosen the path I tread

Knowing it would be steep,

And I will take the joys thereof

And the consequences reap.

|

|

|

|

Ben Potter

Industry Professional

|

Posted: Tue 19 Jan, 2010 1:20 am Post subject: Posted: Tue 19 Jan, 2010 1:20 am Post subject: |

|

|

Here is the days progress, Polished the shell guard, and started the engraving:

Ben Potter Bladesmith

It's not that I would trade my lot

For any other man's,

Nor that I will be ashamed

Of my work torn hands-

For I have chosen the path I tread

Knowing it would be steep,

And I will take the joys thereof

And the consequences reap.

|

|

|

|

Petr Florianek

Industry Professional

|

Posted: Tue 19 Jan, 2010 3:40 am Post subject: Posted: Tue 19 Jan, 2010 3:40 am Post subject: |

|

|

|

i like this one, not my period but beautiful

|

|

|

|

|

Matthew Stagmer

Industry Professional

|

Posted: Tue 19 Jan, 2010 1:06 pm Post subject: Posted: Tue 19 Jan, 2010 1:06 pm Post subject: |

|

|

Lookin good so far Ben.

Matthew Stagmer

Maker of custom and production weaponry

Youtube.com/ThatWorks

|

|

|

|

|

Dustin R. Reagan

|

Posted: Tue 19 Jan, 2010 1:31 pm Post subject: Posted: Tue 19 Jan, 2010 1:31 pm Post subject: |

|

|

| Ben Potter wrote: | 1018 mild steel, wrought it really hard to get on this side of the country, I'm looking for it but it is elusive.

Also, I thought that the steel would work better for this design, |

I bought about 100 lbs of wrought from these folks. Seems to be good stuff, though it took me a couple tries finding the right heat to forge it at (you have to forge it *very* hot -- almost at white heat -- or it crumbles and splits ). I got it in 12" long sections of the 3/4" round and 1/4" x 2" flat. We are relatively local to each other...Let me know, and I'll let you have a piece, at cost, to try out.

The wrought is from an old (late 1800's, i believe?) grain elevator.

http://www.wisconsinwoodchuck.net/price_list_wrought_iron.pdf

Dustin

|

|

|

|

M. Eversberg II

|

Posted: Thu 21 Jan, 2010 10:21 pm Post subject: Posted: Thu 21 Jan, 2010 10:21 pm Post subject: |

|

|

While not my usual interest, I will watch this as it goes along. Your projects are always interesting.

M.

This space for rent or lease.

|

|

|

|

A. Spanjer

|

Posted: Fri 22 Jan, 2010 5:08 am Post subject: Posted: Fri 22 Jan, 2010 5:08 am Post subject: |

|

|

I just have to say, I love this sword.

Great work!

|

|

|

|

Ben Potter

Industry Professional

|

Posted: Sun 24 Jan, 2010 12:12 am Post subject: Posted: Sun 24 Jan, 2010 12:12 am Post subject: |

|

|

Cut in and rounded the background and drilled the holes for the rivets today.

Ben Potter Bladesmith

It's not that I would trade my lot

For any other man's,

Nor that I will be ashamed

Of my work torn hands-

For I have chosen the path I tread

Knowing it would be steep,

And I will take the joys thereof

And the consequences reap.

|

|

|

|

|

Matthew Stagmer

Industry Professional

|

Posted: Sun 24 Jan, 2010 10:07 am Post subject: Posted: Sun 24 Jan, 2010 10:07 am Post subject: |

|

|

I like! Well done on the holes. I know how hard it is to get them lined up just right.

Matthew Stagmer

Maker of custom and production weaponry

Youtube.com/ThatWorks

|

|

|

|

Ben Potter

Industry Professional

|

Posted: Mon 25 Jan, 2010 8:17 am Post subject: Posted: Mon 25 Jan, 2010 8:17 am Post subject: |

|

|

Getting the holes in the right places is a pain.

This piece is domed enough that I couldn't use the drill press and had to do it by hand to get the angles of the rivets right.

Ben Potter Bladesmith

It's not that I would trade my lot

For any other man's,

Nor that I will be ashamed

Of my work torn hands-

For I have chosen the path I tread

Knowing it would be steep,

And I will take the joys thereof

And the consequences reap.

|

|

|

|

Ben Potter

Industry Professional

|

Posted: Tue 26 Jan, 2010 10:28 am Post subject: Posted: Tue 26 Jan, 2010 10:28 am Post subject: |

|

|

Here is another days progress:

I chiseled in the lines of the engraving and did some polishing. it is the details that take forever.

Ben Potter Bladesmith

It's not that I would trade my lot

For any other man's,

Nor that I will be ashamed

Of my work torn hands-

For I have chosen the path I tread

Knowing it would be steep,

And I will take the joys thereof

And the consequences reap.

|

|

|

|

|

|